Nonproliferation Efforts Complicate Medical Isotope Production

(Inside Science) -- A significant change is under way in the production of medicine's most widely used radioactive material, which produces images from the heart to the thyroid, and is employed in at least 25 million medical tests each year in the United States.

The change has implications beyond the medical world, because the traditional means of producing the isotope involves the highly enriched form of uranium used in nuclear weapons.

To reduce the danger of nuclear proliferation, the U.S. Department of Energy's National Nuclear Security Administration is working to minimize nonmilitary uses of this type of uranium, including those that create medical products.

"We are working hard to support the advancement of this commercial industry to meet patient needs while simultaneously advancing nonproliferation objectives and the minimization of civilian use of [highly enriched uranium]," said Anne Harrington, the agency's deputy administrator for defense nuclear nonproliferation.

Companies worldwide are developing alternative methods of creating the medical isotope technetium-99m. The number 99 refers to the combined number of protons and neutrons in this version of technetium and the letter m to the fact that the isotope is metastable; half of it decays every six hours.

As the technetium isotope decays inside a patient's body, it releases gamma rays that a specialized camera captures.

"It's like taking an X-ray from the inside out," said Ira Goldman, project director for strategic supply at Lantheus Medical Imaging, based in North Billerica, Mass. The procedure produces information on body structures from the brain to the kidneys and gallbladder.

The isotope's short half-life has positive and negative effects.

Patients who receive technetium injections for imaging of their hearts and other organs receive very little radiation exposure during their procedures. But to provide sufficient radiation for the images, the isotope must be made just before and during injection.

The source is another radioactive isotope, molybdenum-99. This decays directly into technetium-99m and has a half-life of 66 hours.

The molybdenum isotope is manufactured in the form of tiny particles that are transported to biopharmaceutical companies such as Lantheus in a liquid solution.

Lantheus prepares the isotope for hospital use by mixing minuscule amounts of it with alumina powder in tiny test tube-like columns, which are packed inside lead shielding to avoid handlers’ exposure to radiation.

Throughout the entire process the molybdenum isotope is decaying into technetium.

"When a saline solution is run through, the molybdenum-99 stays in the column while the technetium is picked up by the sterile solution and run into a collection bottle," Goldman explained. "There it can be compounded with a pharmaceutical -- that is, mixed with a non-radioactive powder -- and injected into the patient."

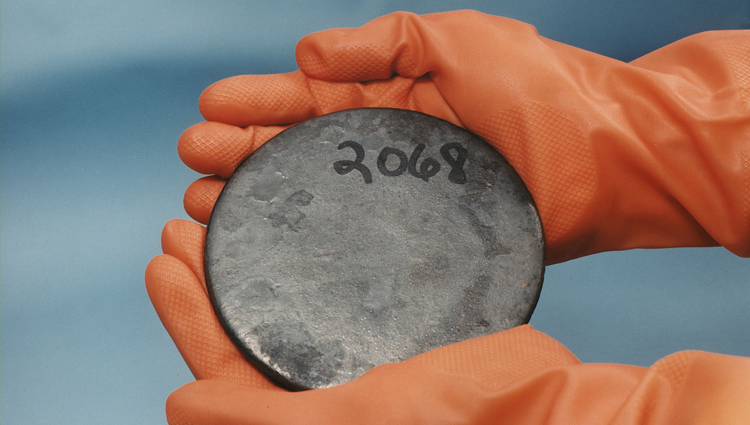

The traditional method of making the molybdenum isotope involves firing neutrons at a uranium target enriched to more than 90 percent of uranium-235, the isotope at the heart of atom bombs.

Most civilian uses that require uranium involve the low enriched form, containing less than 20 percent uranium-235. Nuclear power plants typically use 3-5 percent enrichment.

The need for alternative methods of making molybdenum-99 stems from more than concerns that terrorists might obtain bomb-grade uranium. In 2009, a nuclear reactor in Chalk River, Ontario, Canada that produced a large percentage of the world's supply of molybdenum-99 was taken offline for repairs. That led to a temporary shortage of the isotope, which can’t be stored because it decays so rapidly.

The Chalk River reactor returned to production in 2010, but is scheduled for closure in 2016. Other facilities that manufacture the isotope, including one in the Netherlands, are also reaching the end of their life spans.

In June, the National Nuclear Security Administration announced a series of actions to overcome that problem without adding to the risks of nuclear proliferation.

The agency has given matching grants to four U.S. groups that are exploring methods of manufacturing molybdenum-99 that don't involve highly enriched uranium.

Possible approaches include research reactors converted to use low-enriched uranium instead of highly enriched; a particle accelerator designed to produce medical isotopes from a low-enriched uranium target; a reactor that produces the isotope from a natural molybdenum target; and a particle accelerator-based system that uses a similar target.

"The first two [of the techniques above] can produce molybdenum-99 and other medical isotopes too, and can use the existing distribution network to reach patients," said Gregory Piefer, CEO of Middleton, Wisconsin company SHINE Medical Technologies. SHINE is pursuing an accelerator system that produces isotopes in collaboration with the University of Wisconsin, Madison.

The security agency is also working with overseas producers. In March, it announced that leaders of Belgium, France, and the Netherlands had reaffirmed their commitment to support the use of new processes in their countries by 2015.

Companies in Argentina and South Africa have already developed new methods of manufacturing molybdenum-99 on a small scale without using highly enriched uranium.

Last year, Lantheus Medical Imaging became the first producer in the United States to receive approval to supply molybdenum-99 produced using low enriched uranium and flown in from South Africa.

"This now makes a regular, if minority, portion of our supply," Goldman said.

Lantheus currently accounts for roughly half of American supplies of molybdenum-99. Mansfield, Mass.-based Covidien, supplies about the same proportion.